-

�

目 录

Directory

中文版说明书Chinese version of the manual

概述Outline ………………………………………………………………………3

特点Feature………………………………………………………………………3

技术指标Technical Specifications……………………………………………3

安装及操作说明Installation and operating instructions………………………3

维修Service………………………………………………………………………3

包装及搬运说明Packaging and handling instructions………………………4

印花设备及热转印设备保修单Printing equipment and heat transfer equipment warranty single……………………………………………………4

英文版说明书English manual…………………………………………………5

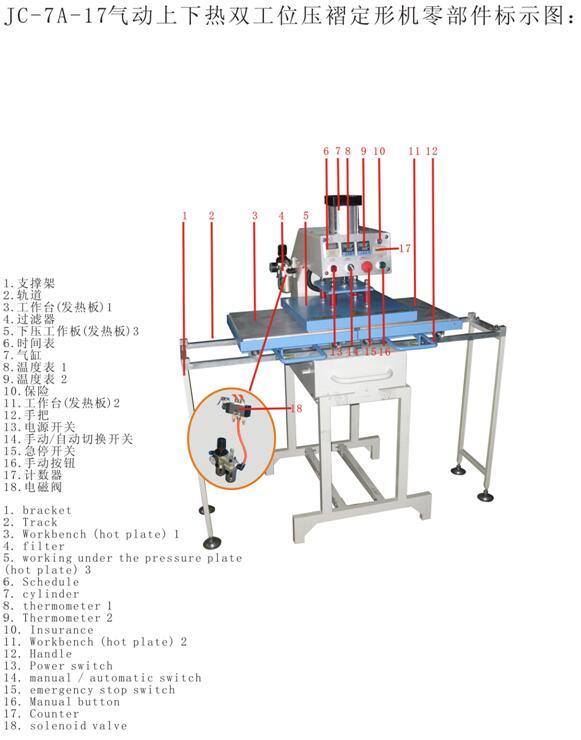

机器零部件标示图Machine parts labeled diagram……………………………………7

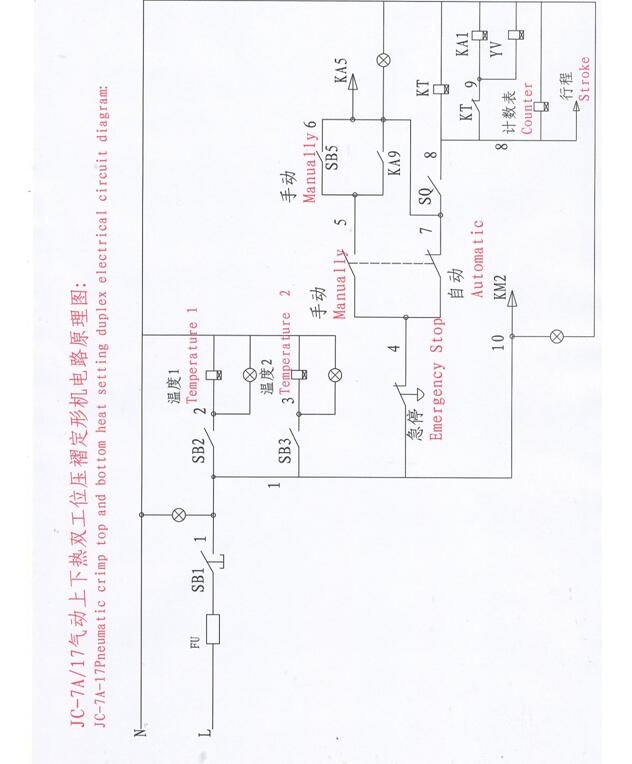

电路接线图Circuit wiring diagram……………………………………………………8

概述

本机(JC-7A/17气动上下热双工位压褶机)可将衣物按要求通过高温及压力的配合压出各种压褶定位效果,操作速度快,省时,省力,是现代制衣压褶工艺中的首选机器。

特点

● 电子数显恒温控制温度,准确性高(±2℃);

● 发热采用进口铝合金浇铸导热原理,省电,温度均匀,温差系数小;

● 电子时间控制,工序完成讯号指示;压力随意调节;

● 机器采用工作发热板左右直线移动,方便烫印,不会移位。

技术指标

电压(V):220/110

功率(KW):6.6 7.5 9.0 10.0 19.5

温度范围(℃):0-399

时控范围(S):0-999

工作台尺寸(㎝): 40×40 40×50 40×60 50×70 60×80

包装尺寸(㎝):135×78×72 135×78×72 150×78×72 98×80×152(附轨道)

98×86×152(附轨道)

安装及操作说明

① 本机要放置在平稳的地面上,机器四周应有一米以上空间,以方便安装及维修。

② 确定机器安装位置后,安装固定好所配脚架,固定好脚架,把机器放有脚架上,放稳机器后,确定机机安装位置后,配备单相220V电压或110V电压交流电源,电压波动范围-10%-5%的闸刀开关或空气开关(注意:电压波动范围-10%-5%时请配备合适的稳压器),以便控制电源通断,并必须接可靠地线。安装完毕后,再认真检查一次,以免误接。(注意:整机必须有合适牢靠的保护地线)

③ 连接所配压缩机气接头,打开气压,将压力表调制(4pB-6pB)使发热板升起,压力最大可调至8 pB;

④ 插上电源,打开电源总开关,电源指示灯随即著亮;

⑤ 将温度表调较至所需温度(通常为120℃-200℃);

⑥ 将时间表调较至所需时间(通常为10至30秒左右);

⑦ 机器准备进入工作状态时请先准备好被压褶定形的相关物品放在易操作机器的附近。

⑧ 操作机器时,机器上设有两个工作台(指工作发热板1与发热板2,以下简称工作台),一个下压工作板(发热板3,以下简称下压工作板),可通过工作台左右水平移动操作完成承印任务。机器上设有自动及手动功能,当用手动功能时,将第一个工作台移动到下压工作板下面,工作台到达指定位置后,按一下手动按钮,下压工作板随即下压,压褶定形指定时间到后,工作下压板上升,接着可移动第二个工作台,重复上动作可完成第二个工作台上的压褶定形任务;当用自动功能时,将第一个工作台移动到下压工作板下面,工作台到达指定位置后,工作下压板随即下压,压褶定形指定时间到后,下压工作板上升,接着可移动第二个工作台,重复上动作可完成第二个工作台上的压褶定形任务。

⑨ 该机型为专用于压褶定形机器,不需要配备其它物品,如硅胶等。

维修

1. 压力:下压发热板不平时,可调较发热板中心的四条丝杆;如压力不够时,可调较机器的过滤器,把过滤器上高突起的左边盖子拔起,顺时针是增加压力,逆时针是减少压力,注意:压力最大可调至8PB。

2. 时间:当压褶定形时间到达而发热板未升起,则须检查电磁阀触点是否烧坏或时间表是否烧坏。

3. 温度:当所调温度到达时,温度表会显示已到所需温度,如不升温,则检查①接触器是否坏了;②温度表是否失灵;③发热管是否烧坏;④高温线是否脱落。

4. 下压工作板不下压:①检查工作台是否到位;②气压是否在4pB以上;③感应开关是否与磁铁感应;④时间表是否计时,会计时,则说明感应开关没问题则需检查电磁阀;⑤电磁阀是否有电,有电而不动作,则是电磁阀坏。

注:气压力应调到(4pB-6pB),如发热板未升起,请栓查气压线路,电磁阀是否畅通,过滤器是否打开。

包装及搬运说明

① 40×60规格以下(含40×60规格)当客户指定用木箱包装时:用可承重100公斤以上叉车搬动;不用木箱包装时,可两到三个两手抓紧机器前后手把位置平稳抬动机器,轻轻放下即可。40×60规格以上,当客户指定用木箱包装时,因本机主机下方装有活动脚轮及脚杯,用木箱包装时,为安全及防止机器跑位,请一定切记把四个脚杯全部调至接触到木箱底盘表面固定不能随意移动后方可包装,用可承重150公斤以上叉车搬动。

② 40×60规格以下(含40×60规格)当客户指定用木箱包装时:用可承重100公斤以上叉车搬动;不用木箱包装时,可两到三个两手抓紧机器前后手把位置平稳抬动机器,轻轻放下即可。

印花设备及热转印设备保修单

产品型号: □JC-7A/17上下热压褶定形机 出厂编号:

保修条例

1. 在保修期内凭此单和送货单(或收款收据)修理;

2. 保修期限:从出售起为一年。

3. 保修注意事项:

◆ 凡未经拆动,确属产品制造不良的故障或损坏,均由我厂负责修理或更换损坏的零配件;对使用不当等人为制造的故障或损坏,不属保修范围;

◆ 非电器配件不在保修范围;

◆ 用户与我厂联系解决质量问题时,请写明机器型号,出厂编号,故障现象。

Outline

The machine (JC-7A/17 pneumatic crimp top and bottom heat duplex unit) can be clothing as required by high temperature and pressure with pressure crimp positioning of a variety of effects, operating speed, saving time, effort, is the modern system clothing pleating process of choice for machines.

Feature

Electronic digital thermostat control temperature, high accuracy (± 2 ℃);

Fever imported aluminum alloy casting thermal principle, power, temperature uniformity, temperature coefficient is small;

Electronic time control, process completion signal indication; pressure adjustable;

Machine uses linear movement working around hot plate for easy stamping, will not shift.

Technical Specifications

Voltage (V): 220/110

Power (KW): 6.6 7.5 9.0 10.0 19.5

Temperature range (℃) :0-399

When the control range (S) :0-999

Table Size (cm): 40 × 40 40 × 50 40 × 60 50 × 70 60 × 80

Packing Size (cm): 135 × 78 × 72 135 × 78 × 72 150 × 78 × 72 98 × 80 × 152 (with Rails)

98 × 86 × 152 (with Rails)

Installation and Operation Instructions

The confidential placed on a stable ground, around the machine should be more than a meter space to facilitate the installation and maintenance.

Determine the machine installation location, the installation fixed dispensed tripod, fixed tripod, tripod placed on the machine, put the stability of the machine, confirm their installation location, with a single-phase voltage 220V or 110V AC power supply voltage, voltage fluctuation range -10% -5% of the knife switch or air switch (Note: The voltage fluctuation range -10% -5% when equipped with a suitable regulator) to control power on and off, and must be connected to a reliable ground . After installation, carefully check once again, in order to avoid incorrect connections. (Note: The machine must have the proper protection of solid ground)

Connection with a compressor gas fittings, open pressure, the pressure gauge modulation (4pB-6pB) the heating plate rises, the pressure is increased to a maximum 8 pB;

Plug in the power, turn on the power switch, power indicator light then forward;

The thermometer adjusted to the desired temperature (typically 120 ℃ -200 ℃);

Will be adjusted to the desired schedule time (usually 10-30 seconds or so);

When the machine is ready to enter the working state ready to be pressed pleats please amorphous related items placed near the machine easy to operate.

Operating the machine, the machine is provided with two tables (refers to the work with a heating plate heating plate 2, hereinafter referred to as bench), a work under the pressure plate (hot plate 3, hereinafter referred to as the work under the pressure plate), through the work Taiwan about the level of move operation is complete printing task. Machines equipped with automatic and manual functions, when using the manual function, the first table is moved to work under the pressure plate below the table arrived at the designated location, click the manual button, under the pressure of job boards immediately under pressure, pressure after the specified time to tuck amorphous, working up under the plate, followed by a second movable table, repeat the action to be completed by the second crimp workbench amorphous task; when the automatic function, the first table move to work under the pressure plate below the table to reach the designated position, working under the plate immediately under pressure, crimp setting specifies the time to post, under the pressure of rising job board, can then move the second table, repeat the action to be completed the second work bench crimp setting tasks.

The model is designed to crimp setting machines with no other items, such as silica gel.

Service

Pressure: heat plate is not usually under the pressure, adjustable heating plate center four screw; such as pressure is not enough, adjustable machine filters, the filters on the left side of the lid uprooted high protrusion clockwise to increase pressure and counterclockwise to reduce pressure, attention: the greatest pressure adjustable up to 8PB.

Time: When crimp positioning time is reached while the heating plate is not raised, it shall check whether the solenoid valve contacts burned or timetable is burned.

Temperature: When the temperature reaches tune when the thermometer will display to the desired temperature, if not heat up, check whether the contactor ① bad; ② thermometer is malfunctioning; ③ heat pipe is burned; ④ temperature line is off.

No less than the pressure plate under the pressure of work: ① Check the table is in place; ② whether 4pB above atmospheric pressure; ③ sensing switch and magnet induction; ④ whether the timing schedule, accounting, then the description of sensor switch no problem need to check the solenoid valve; ⑤ solenoid valve if there is power, there is power without action, the solenoid valve is bad.

Note: The air pressure should be adjusted (4pB-6pB), such as the heating plate is not raised, please check the air pressure line bolt, solenoid valve is open, the filter is turned on.

Packaging and handling instructions

40 × 60 size less (including 40 × 60 size) When the customer specifies use wooden packaging: can load 100 kg with a forklift to move; without wooden packaging, you can grasp with both hands two to three locations around the machine steady hand lift the machine gently down to. 40 × 60 specifications above, when the client specifies packed in wooden cases, because of the local host is equipped with casters and feet below the cup, packed in cases when, for safety and to prevent the machine moves, be sure to remember the four foot cups All raised to come into contact with the surface of the fixed wooden chassis can move freely before packing can load more than 150 kilograms with a forklift to move.

40 × 60 size less (including 40 × 60 size) When the customer specifies use wooden packaging: can load 100 kg with a forklift to move; without wooden packaging, you can grasp with both hands two to three locations around the machine steady hand lift the machine gently down to.

Printing equipment and heat transfer equipment warranty

Product Type: □ JC-7A/17 pressing down pleats positioning machine factory number:

Warranty

1.During the warranty period virtue of a single and delivery note (or payment receipt) repair;

2.Warranty period: from the sale of up to one year.

3.Warranty Note:

◆Whatever is not dismantled, indeed poor manufacturing faults or damage, are responsible for the repair or replacement of our plant damaged parts; against improper use of artificially created failure or damage is not covered under warranty;

◆Non-electrical accessories not covered under warranty;

◆Users contact with my factory to solve quality problems, please specify the machine type, serial number, failure phenomenon.